Elevate Your C10 with Premium American Parts

Explore our exclusive range of MADE IN USA custom chassis, radiators, and more, crafted for enthusiasts. Powered by Innovation.

Welcome to Modern C10, where our passion for C10 trucks shines in every American-made part we craft. Our small, expert team puts heart into each high-quality piece, ensuring you get the best for your DIY projects. Let's build your dream truck together!

1963-1987 C10 Build Our Own Front Suspension Kit

1963-1987 C10 Coilover Conversion. All parts are high quality and Made in USA.

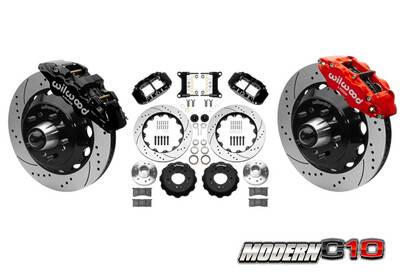

Steel Drop ProSpindle

Wilwood's C10 Steel ProSpindle Kits contain a pair of one piece spindles and integrated steering arms for 63-87 Chevrolet & GMC 2WD C10/C15 Pickups, Blazers and Suburban's, dependent on part number. Specifically designed for use with Wilwood's disc brake kits and with a 2.50" drop for a more aggressive stance without affecting steering geometry. Constructed from a proprietary grade of cast steel with a traditional bearing snout that supports Wilwood kit specific hubs in both 5 x 4.75" and 5 x 5.00" wheel bolt circles.

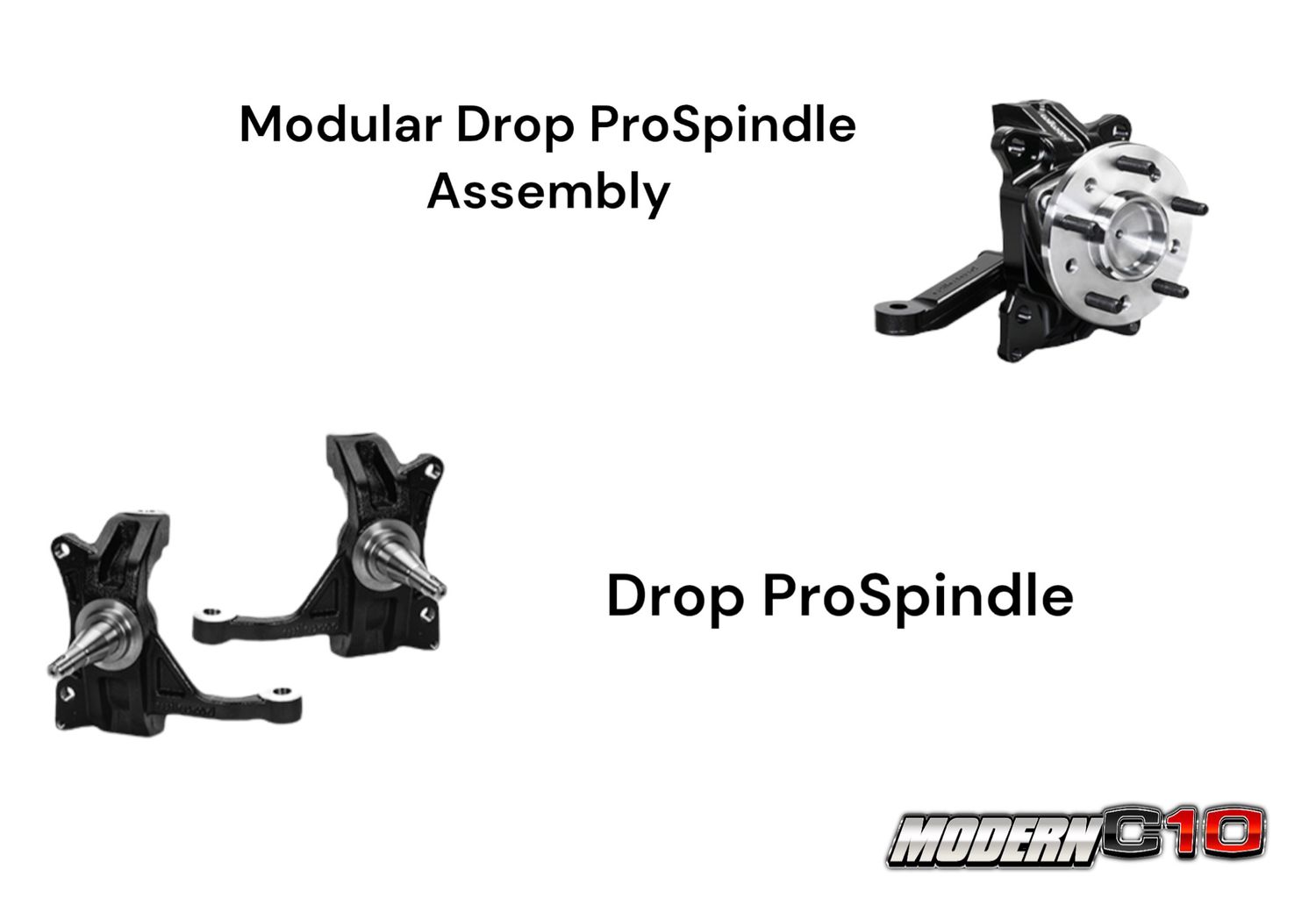

Modular Drop ProSpindle Assembly

Wilwood’s ProSpindle Kits contain a pair of Modular Spindles, steering arms and hubs assemblies for either 63-70 or 71-87 Chevrolet & GMC 2WD C10/C15 Pickups and Suburban’s. Specifically designed for use with Wilwood’s disc brake kits, with a 2.50” drop for a more aggressive stance without affecting steering geometry. Constructed from a proprietary grade of forged aluminum with an integrated modular bearing hub assembly that supports both 5 x 4.75” and 5 x 5.00” wheel bolt circles. Direct mounting for radial caliper brackets create strong, zero flex platform for brake mounting.

Front Upper “StrongArms”

Front upper tubular control arms for lowered Chevy and GMC C10, C15 and C1500 trucks. Designed to be used CoolRide air suspension system or as factory replacements.

Development – StrongArms™ are developed by Ridetech® in Jasper, Indiana on an actual running, driving vehicle. This allows us to properly address ALL fitment and performance issues. It also allows us to document an installation, demonstrate the installation to our sales techs and dealers, and allows ongoing evaluation of the performance of the StrongArms™

Components – Powder coated in a satin black finish and completely assembled with ball joints, bushings and cross shafts. To reduce deflection and stiction from the suspension movement Injection Molded Delrin Bushings are used, which are also impregnated with Teflon to eliminate the need for lubrication.

Geometry – Properly designed control arms will add more positive caster and will position the wheel in the wheel opening for maximum clearance. Ball joint angles are repositioned to prevent binding.

Front Lower “StrongArms” (Factory Coil Spring Style)

Design – We think the best way to design any component is to keep it simple. That is why Strong Arms™ are designed with as few components as possible. We have a new 4 axis tubing bender that allows precise, repeatable bends that no other machine can achieve. We can create elegant tubing bends that would otherwise require several separate welded components.

Geometry – Geometry of a suspension starts with the position of the frame mounts and the height of the spindle, not the shape of the control arm. However, there are a few small things in control arm design that can make a big difference in how a vehicle drives and performs.

- We create extra caster potential by adjusting the fore and aft position of the ball joints. At the same time we make sure the wheel is properly positioned in the wheel well so your new 18″ wheels fit like they should!

- The ball joint camber travel is re-centered to accommodate the new lowered ride height so the ball joint doesn’t bind during extreme suspension movement.

- The perimeter of the StrongArms is contoured to allow maximum wheel clearance and turning radius.

- All shock mounts, air spring mounts, and sway bar mounts are integrated into the design so you don’t have to finish the engineering in order to enjoy your ride!

StrongArms™ are optimized to allow proper camber adjustment at your new lowered ride height without using a large stack of shims.

Front Lower “StrongArms” (Bagged Conversion Style)

Development – StrongArms™ are developed by Ridetech® in Jasper, Indiana on an actual running, driving vehicle. This allows us to properly address ALL fitment and performance issues. It also allows us to document an installation, demonstrate the installation to our sales techs and dealers, and allows ongoing evaluation of the performance of the StrongArms™

Components – Powder coated in a satin black finish and completely assembled with ball joints, bushings and cross shafts. To reduce deflection and stiction from the suspension movement Injection Molded Delrin Bushings are used, which are also impregnated with Teflon to eliminate the need for lubrication.

Geometry – Properly designed control arms will add more positive caster (without a pile of shims) and will position the wheel in the wheel opening for maximum clearance. Ball joint angles are repositioned to prevent binding.